As China's economic development, social power consumption is also increasing, carrying high voltage electrical equipment such as transformer power transmission task. Transformer, high voltage switch cabinet, power load switch are increasing rapidly, the connection points between the large number of high-voltage electric power network equipment and the equipment is the weakest link in the power transmission, because in the long run, these connection points for oxidation corrosion and aging or because of the looseness of the fastening bolt and other reasons to make contact resistance increases, and as the load increased and fever, Wen Sheng, expansion, contraction, oxidation, resistance increases, forming a vicious spiral rise again until the accident. According to statistics bulletin of national electric power safety accident, in our country every year only in the accident of electric power station. 40% is composed of high voltage electrical equipment due to overheating, so the change of temperature monitoring system for high voltage connection point is very necessary. The online temperature monitoring is an important means to ensure the safe operation of the high-voltage equipment.

Common methods of measuring two, high pressure environment temperature

Wax temperature measurement is based on a change color wax tablets judging the measured temperature, popular application at present. Has the advantages of simple, low cost. Disadvantage is the low accuracy, poor reliability, not quantitative measurement. Thermal infrared temperature measurement technology is a non-contact temperature measurement. Has the advantages of large measuring range, high accuracy, high reliability. Drawback is that expensive equipment. The above two methods need a large number of human conduct regular survey, unable to realize the real-time online monitoring of temperature. And the heavy use of handcart type switch cabinet breaker Xiao of the movable secluded location. The above two methods have been unable to temperature.

The optical fiber grating temperature measurement technology is the use of grating as temperature sensor, it is to realize the temperature measurement using the linear relationship between the reflection wave length and temperature. Drawback is that fiber easy to break, easy to break, not high temperature. Although the fiber itself is insulated, but in the accumulation of dust, especially in the humid environment is easy to make the insulation performance degradation, affect the operation safety.

Electronic component temperature technology is the use of electronic temperature sensor temperature measurement. The temperature sensor is at the point of measurement, high accuracy, fast response, easy to realize real-time online monitoring of temperature. The temperature sensor to receive and display the data transmission device can be divided into two kinds of optical fiber transmission and wireless transmission. A wireless transmit mode can be divided into infrared transmission, GSM technology, ZigBee technology etc.. Optical fiber transmission mode has effect on the safe operation, infrared transmission way has strict requirements on the installation environment, inconvenient installation and debugging, afraid of shock, fear of dust.

Technical characteristics of three, this product

This product is the leading domestic level of high voltage equipment contact temperature online monitoring system - this system unique design concept, the wireless transmission temperature signal, the ideal to realize the electrical isolation of a high-pressure equipment and two monitoring equipment, to ensure the safe and reliable operation of the system, is a new high-tech product a in the maintenance of the safe operation of electric power, has extensive application value and prospect, is a revolution of the traditional temperature measurement methods.

This product uses the temperature of electronic components and wireless transmission mode of combining advanced, will be close to the special sensor to the contact pressure switch, bus etc.. Point near, convenient installation, direct measurement of the temperature. The temperature information transmission by radio frequency technology, the sensor and the measured point potential, safe and reliable, sensor by high energy lithium battery powered, for as long as 5 years. Each receiving device has 12 channels for users. And is equipped with liquid crystal display real-time display of all tested temperature, alarms are normally open and normally closed two groups of signal output nodes, device with standard RS485 serial communication port, temperature monitoring network and PC connected to as many as 128 taiwan. And provide a host computer receiving, storage, printing, data analysis software. Also through the LAN will upload all data.

Wireless transmission using the most advanced ZigBee technology, radio frequency standard with IEEE802.15.4. Avoid the application frequency of the use of 2.4G, direct sequence spread spectrum (DSSS), stronger anti-interference ability. Transmission power very low to ensure the long service life of battery.

The product can not only save a lot of manpower, material resources, compared with other kinds of temperature measurement way, also has the following advantages:

1, high safety

The temperature sensor and the measured point potential, using temperature data transmission technology, without any external connection. The optical fiber temperature measurement with optical fiber, so as to reduce the security.

2, high reliability

Radio frequency technology is not influenced by the vibration and the dust, and the infrared temperature measurement method will cause vibration, dust and reduce the reliability and accuracy of temperature.

3, convenient installation

The temperature sensor has the advantages of small size, can be easily installed in the switch contact, cable joints and other small installation space of the measured point, no wiring and receiving apparatus, and optical fiber temperature measurement methods need to place fiber, infrared temperature measurement method to adjust the receiving device location, installation is not convenient.

4, free debugging

Electricity can be used, without debugging. Because of convenient installation and adjustment free, suitable for outage time is short, the installation project within a short period of time.

Four, the temperature sensor and installation dimensions

Wireless temperature sensor is integrated structure, internal use of high temperature and high energy lithium battery, built-in LTCC antenna, the external use of high temperature and high pressure heat shrinkable tube packaging, waterproof and dustproof, small volume. Operating temperature measurement of dynamic contact, the most suitable sub switch cabinet lead cable joints and busbar connection point, can also be used for outdoor high-voltage equipment. Dimensions: 56mm × 27 mm × 17mm, shown in Figure 4-1 shows the shape.

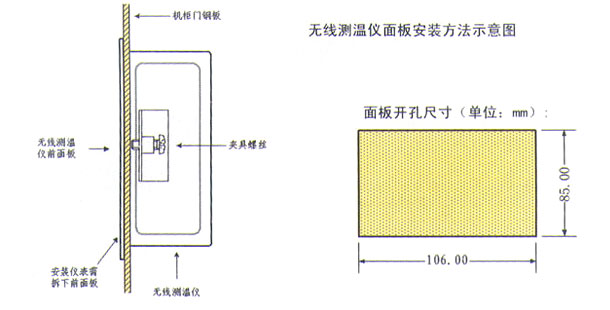

Wireless temperature sensor of bottom surface is the temperature of surface objects, in order to accurately measure the surface temperature, should ensure close contact surface temperature sensing surface and the object to be measured sensor. When installed with high temperature nylon cable ties or by other methods such as paste will be fixed on the object measured, installation is shown in Figure 4 - 2 shows.

Five, the temperature monitor and installation dimensions

Wireless temperature monitor is a dish display, liquid crystal display with backlight, can also clearly shows that even in a dark place. Usually installed in the two chamber switch cabinet door, opening size is 106mm (wide) x 85mm (high), installation diagram as follows:

Six, wireless temperature measurement system

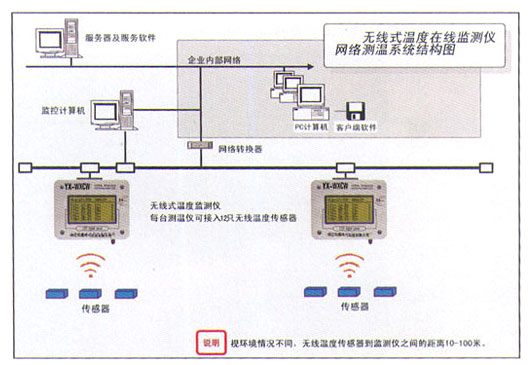

By running the continuous temperature monitoring of the measured points can be determined, degree of superheat, when the absolute limit temperature or temperature change rate exceeds the limit, the system can timely warning and alarm. The system adopts a computer center, through RS485 industrial bus, connected with a temperature monitor, a temperature monitor up to 128 can be composed of a wireless telemetry network, each temperature monitor is equivalent to a wireless access point, it can access 6~12 wireless temperature sensor, temperature online monitoring center computer systems of all the measured temperature monitor, the system composition structure as shown below:

Seven, software system

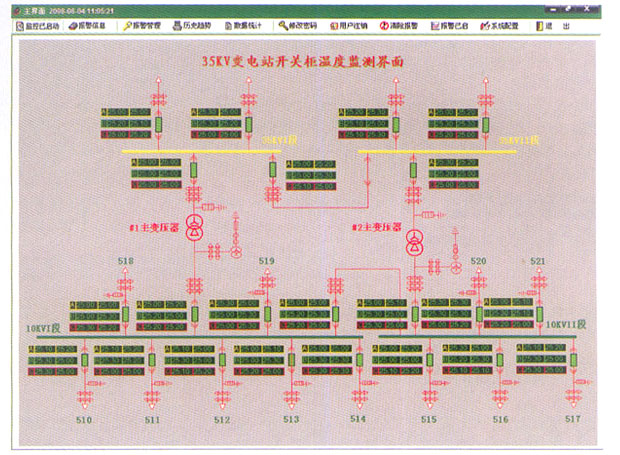

The real-time online monitoring and management analysis software of temperature pressure equipment is a set of specialized for real-time monitoring and data of temperature of high voltage equipment management and analysis software system, the software running on the host computer, can realize temperature display, historical data analysis, recorded and compared pre alarm and alarm, running the whole record and report printing function. Help the temperature variation operator monitoring and comparative analysis of high-pressure equipment monitoring points, to predict the fault location, so as to ensure the safe operation of the high-voltage equipment. The software requires a separate order. Software interface is as follows:

Eight, the main technical parameters

|

Cabinet display module voltage

|

AC220V or DC220V

|

|

Single channel

|

6~12

|

|

The measuring range

|

-55 ℃ ~+125C

|

|

Measurement accuracy

|

± 0.5 ℃

|

|

Resolution

|

0.1 ℃

|

|

Temperature sensor battery life

|

More than 5 years

|

|

High voltage withstand voltage

|

95KV

|

|

Lightning impulse voltage

|

185KV

|

|

Power supply terminal insulation resistance against ground

|

185 ≥ 100M Ω KV

|

|

Power terminals on the power frequency withstand voltage

|

2000V (1min)

|

Nine, the scope of application

1, 110KV online monitoring of various dynamic and static contact and junction temperature of high voltage switch cabinet cabinet following within.

2, 110KV online monitoring of high voltage cable joints the underground cable trench and other high voltage bus connector temperature.

3, on-line monitoring of substation high voltage equipment temperature.